3D Electrical designs:

How digital twin technology simplifies your control panel design and production

A digital twin is a virtual representation of an object or system. It contains real-time data and information that allow engineers to assess a design without the need for a physical object. Embracing digital twin technology can help drive innovation in product design and development for manufacturers, as well as greatly improving efficiencies in operations and maintenance. With its accurate data, digital twins are transforming how businesses develop, manage, monitor and optimise their products or services, to reduce costs and enhance customer experiences.

Is your panel building heading in the right direction?

Let’s take this journey together!

Are your electrical design teams and control panel building teams worlds apart?

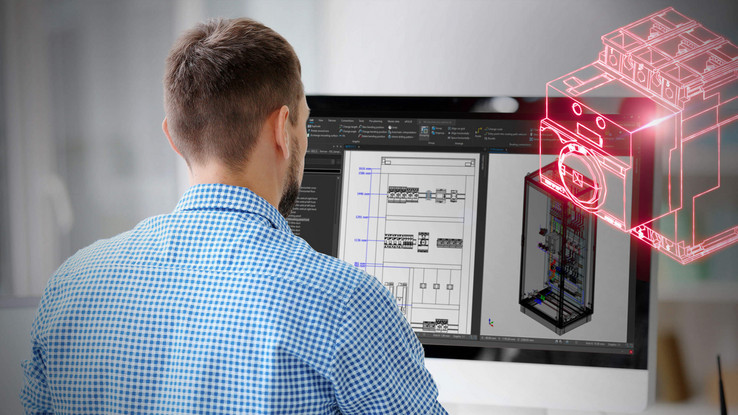

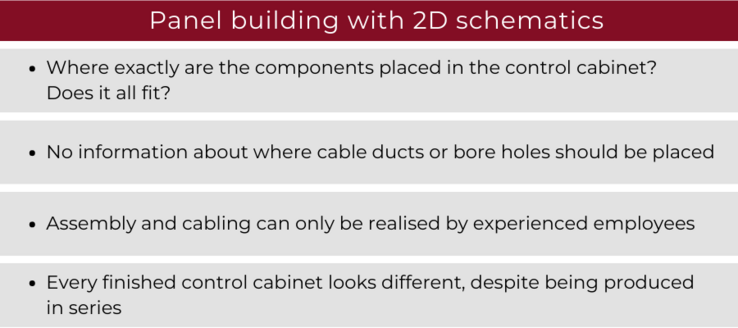

As an Engineering Manager, you probably feel the need to keep an eye on how your colleagues on the shop floor are bringing your designs to life. When two-dimensional schematics are passed from the engineering department to production, errors can quickly crop up as certain useful information is missing.

Where exactly do components need to be placed on the mounting plate? Is it clear where the drill holes need to be cut out? And the operating elements on the door? Where should the cable ducts, DIN rails and terminals be installed? If there aren’t any exact specifications, various queries from the production team and the client are inevitable.

Thanks to 3D design, EPLAN can provide this information

3D design is ready to combat the challenges and errors that come about from 2D schematics. EPLAN's 3D capability gives design engineers all the tools they need to create complex and highly detailed digital twins for electrical control panels. The software allows engineers to visualise how components will fit into the panel, identify possible collisions, find the optimum wiring route and check to provide cooling to the potential hot spots.

Using data from the schematics created in EPLAN, you can compile important information for materials procurement. Then, the EPLAN project data is the perfect foundation for deriving a realistic digital twin of the planned control panel. The right 3D software makes it easier for both electrical engineers when designing the control panel, and for technicians when producing it.

2D schematics vs 3D designs

Result: Queries, re-working and a lack of personnel waste both time and precious resources.

Result: Virtual prototype for fast panel building and smooth approval processes.

In this e-book we take you into the world of 3D design, showing you 6 reasons why you, as a future-oriented electrical engineer, cannot ignore the prospect of 3D. These include ensuring a more efficient work process, providing clear and error-free drawings and creating opportunities to scale up in busy times.

Virtual prototyping can give companies decisive advantages; ensuring better collaboration between engineering, panel building and other downstream processes. Check out these four important advantages for using virtual prototypes for your processes in control panel design and construction.

Using EPLAN Software to create 3D control panel designs

There’s still a lot to do after you've created your schematics. But EPLAN will be with you every step of the way, enabling you to work more efficiently, accurately and keeping costs down. For example, EPLAN provides you the software for the 3D designs of your control and switchgear systems. EPLAN also gets used on the production floor to simplify control panel manufacturing based on the digital twin.

Take a look at the EPLAN products below to see how EPLAN can support the process from design to finished product.