Automated panel production:

From the digital twin to the finished control panel in record time

Do you worry about a shortage of skilled personnel for your control panel manufacturing? Lift this concern off your shoulders with EPLAN. Thanks to EPLAN software and perfectly matched manufacturing equipment from Rittal, you can save working hours and resources by automating repetitive manual processes and reducing errors. Implementing automation means you can use qualified personnel in a more targeted manner, while less-experienced workers can quickly produce control panels.

Is your panel building heading in the right direction?

Let’s take this journey together!

A skilled-worker shortage in panel production

Are your order books full, but it's a struggle to complete existing projects? Often this is because it's not easy to find qualified personnel, especially for highly technical jobs in panel production, such as wiring. Perhaps the company would love to take on more business, but long-term employees already have their hands full doing day-to-day work for control panel assembly. Between drilling patterns, crimping cables and wiring according to the electrical schematics, there simply isn’t time for taking on additional projects. At the same time, clients are turning up the heat: both volume production and highly customised production for one-of-a-kind items must be delivered as quickly as possible.

The solution: 3D models, assistance applications and automated machines

If your design department plans control panel layouts in 3D, the data from the engineering designs can serve as the technical specifications for production equipment. For instance, mounting plates can be drilled fully automatically, or cables routed in 3D can be cut-to-length and crimped. This reduces errors, and vastly reduces work times; making happy customers and increasing order capacity.

Easy control panel assembly

- Easily generate manufacturing drawings and cutting lists for cable ducts

- Use 3D routing to determine cable lengths

- Use equipment for component labelling or automatic crimping machines

- Step-by-step guides for cabling and component placement based on 3D data

⇒ The 3D model supplies lists and instructions for production

Automated panel production

- Use the data for order processing and production management

- Seamless data transfer to manufacturing machines for automated cabinet modification

- Automatically cut, crimp and bundle cables using data from the 3D model

⇒ The 3D model delivers the data ready for the automated manufacturing machines

Automation and digitalisation are essential building blocks for Industry 4.0 and their implementation depends on the deployment of well-designed and well-manufactured control cabinets and switchgear. To support this need, EPLAN has researched ways in which the design and manufacture of control cabinets and switchgear can be made easier and more efficient. Download the full study free of charge to uncover the key findings of the study.

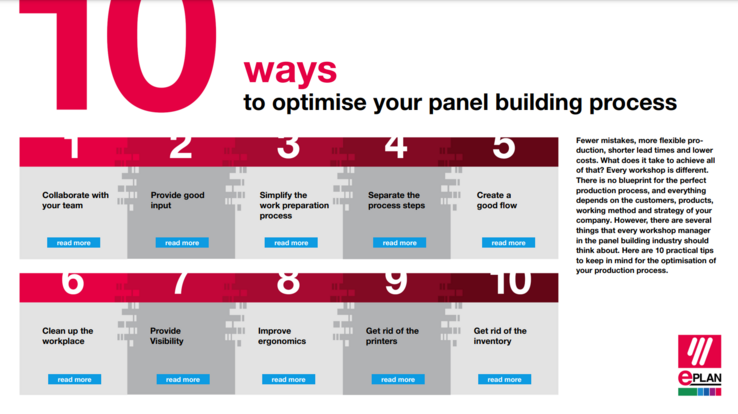

Fewer mistakes, more flexible production, shorter lead times and lower costs. What does it take to achieve all of that? Every shopfloor is different. There is no blueprint for the perfect production process, and everything depends on the customers, products, working method and strategy of your company. However, there are several things that every workshop manager in the panel building industry should think about.

Here are ten practical tips to keep in mind for the optimisation of your production process.

Take full advantage of the momentum from the design department for panel building with Rittal and EPLAN

Everything from a single source: Rittal and EPLAN supply you with software, services, tools and manufacturing equipment for your entire value chain in control panel manufacturing. The various solutions from these affiliated companies are perfectly in sync, letting you seamlessly transfer data from the EPLAN electrical designs to be used to operate manufacturing systems from Rittal for automated control panel manufacturing.

But what if you have existing manufacturing equipment from another supplier? Don’t worry, EPLAN can export to many other types of manufacturing machines in addition to Rittal.

Automated panel modification

Simply set the mounting plate, and then the manufacturing system automatically drills holes and mills threads, not to mention cuts any notches in the panel. The required data is taken from the 3D model of the control panel created with EPLAN software. This eliminates the need for manual data entry, which reduces the possibility of human error.

Preparing cables for wiring

Cutting to length, labelling, crimping and bundling cables all happens automatically with the Rittal Wire Terminal. Preparing the cables can take place parallel to the cabinet modifications based on the virtual prototype of the control panel created in EPLAN. Cutting all labels to exact lengths based on data and performing the task in parallel reduces cabling waste and results in faster control panel manufacturing.

Digital instructions for assembly and wiring

On a tablet or monitor, the software guides technicians through the manual assembly and wiring of a control panel using step-by-step instructions. This enables several employees to work on the same or multiple control panels at the same time, even with little prior experience. The current processing status for assembly and cabling is clearly shown within the software, and can be viewed on a centralised dashboard to show the progress of all panels in production.

Virtual control panel documentation repository

Put an end to hundreds of pages of outdated paper documentation during the ongoing operations of machines and plant systems. With the Rittal ePOCKET, you can share up-to-date machine and plant system documentation and access selected Rittal control panels directly via QR code. This makes maintenance and servicing easier.