Automation Technology

Automation Technology in Machinery and Plant Construction

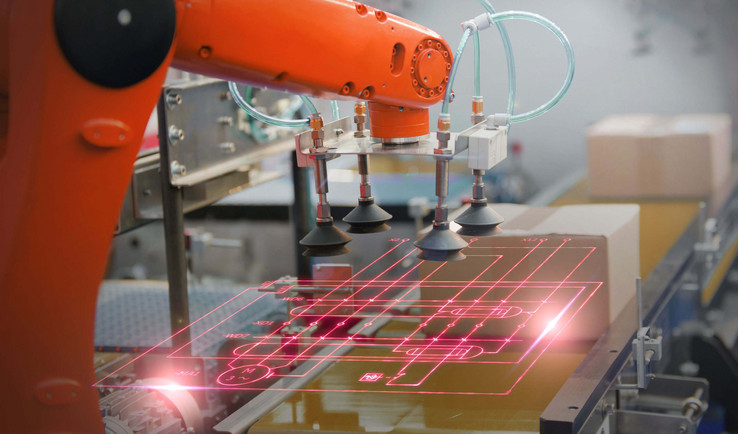

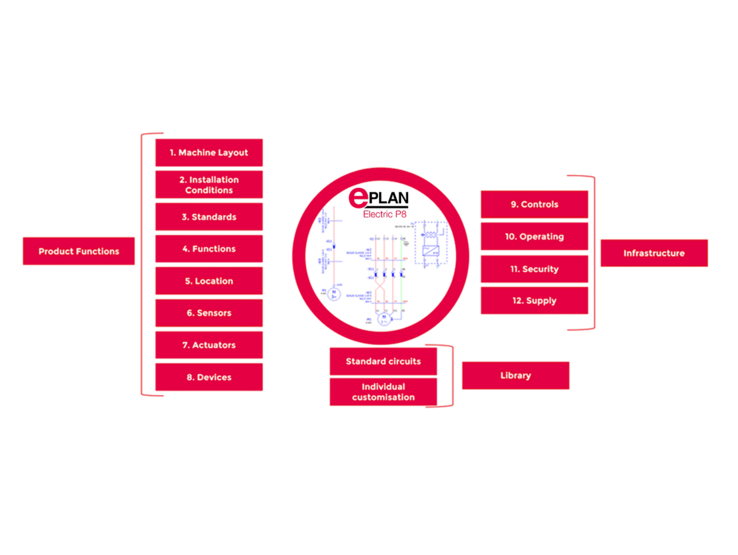

Automation technology comprises the design of sensors and actuators, their regulation and the controls for machines as well as the communication between systems. All components are represented in the schematics. With the EPLAN Project, you can create a complete digital image of the schematics and a digital twin for the control cabinet technology. This serves as the central source of information for all components and machine data for your engineering and manufacturing departments. In terms of digitisation and automation, our goal is to enable you to create your schematics with as little effort as possible.

Automation Technology – What Is It?

Automation technology is its own independent discipline. It is used in all areas of technology for engineering machines and plant systems. With the solutions from EPLAN, you have an enormous range of functions for this discipline at your fingertips.

What Possibilities for Automation Does EPLAN Offer You?

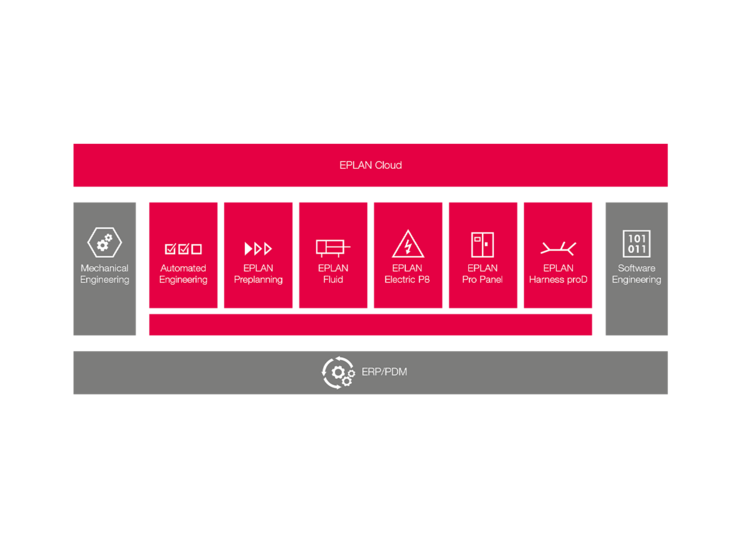

EPLAN supports you in setting up your engineering processes across all disciplines. For you, this means a significant efficiency increase when working on your EPLAN Project because your digital data flows seamlessly from solution to solution becoming further enhanced in every step of the process.

Discover how to enhance your value chain in this guide

To optimise a company’s performance, all processes should be scrutinised, particularly ones that have been used with very little alteration over a long period of time. By combining value-enhancing process steps in engineering, design, work preparation, production and maintenance, it’s possible to create a sound foundation for all efficiency improvements.

This is the value chain, a business model that describes the full range of activities needed to create a product or service. Download this free guide to see how you can save money, time and increase your competitiveness by enhancing your value chain.

Automation in Theory and Practice

The European 4.0 Transformation Center (E4TC) at RWTH Aachen University has investigated the strategic digitisation of the engineering and control technology design of machine and plant systems.

Three Phases of Automated Engineering

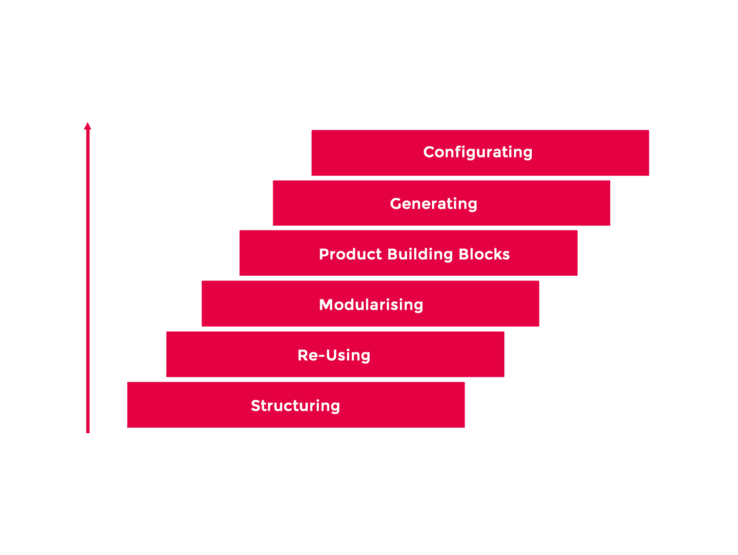

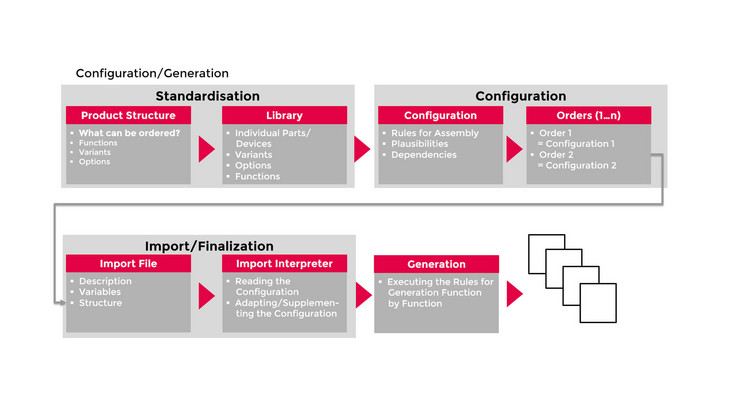

What specific approaches do companies take to successfully automate their engineering processes? The efficiency study also delivers informative results in this area: the basis is the structuring of re-usable functions such as variants or options. These functions are described in partial circuits and centrally administered in macro libraries. Schematics for new orders can be compiled more quickly with this modular, function-oriented product structure. If product or sales configurators are being used in a company, this ordering data can be directly imported. The result: schematics are generated either through dialogue guidance or completely in the background and fully automatically on the platform or through a web application.

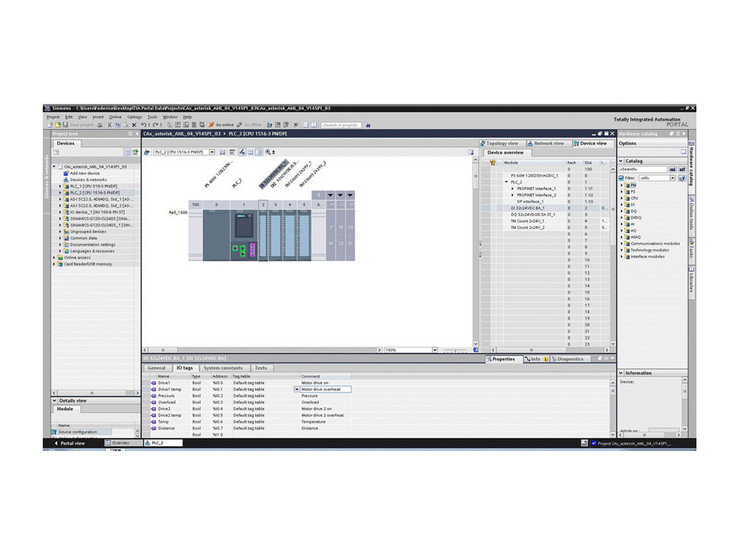

PLC Controls and Exchanging Assignment Lists

Control technology is a branch of automation technology and an important area of responsibility for EPLAN users. An overview of the relevant topics and useful services.

We’re Happy to Help!

Would you like to find out more about our solutions or are you interested in our services? Then contact us – we’re here for you!