EPLAN Smart Wiring | Your Electrical Panel Wiring Assistant

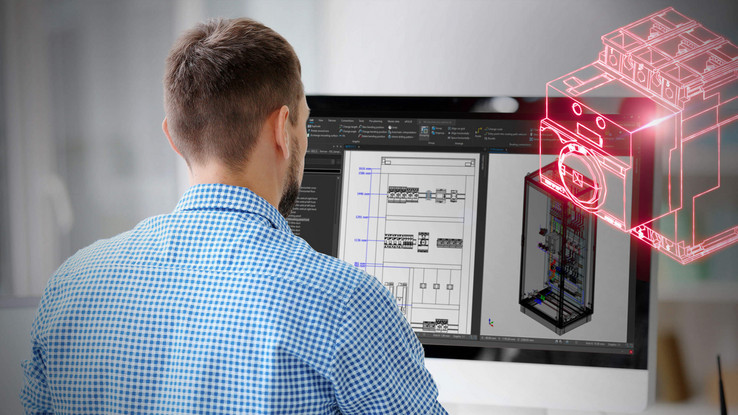

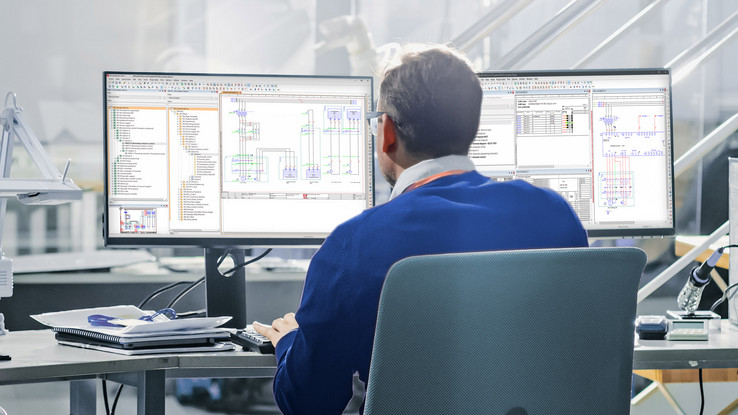

EPLAN Smart Wiring is your virtual assistant for manual wiring in control panel construction. From the connection point to the exact wire routing, the software provides the wiring technician all the necessary information in digital form – also in 3D when required.

Step-By-Step Wiring of Control Cabinets

As a wiring technician, you receive detailed, step-by-step instructions for easy implementation. You decide whether you want to wire the displayed routing connections individually or in a fixed sequence. The wiring status can be noted via a red/yellow/green traffic light principle.

Wiring is possible even without the schematics, which are stored in the assistant. For checking and reference purposes, you can access the schematics – starting from each individual connection.

Easy-to-read visualisation of mounting layout, devices, connections, connection types and wire routing.

If there are last-minute changes, you can perform an automatic project comparison to avoid errors. You can forward any anomalies directly to the engineering department via e-mail.

Project data are provided from a central server to enable identical control cabinets to be manufactured in parallel and for several wiring technicians to work simultaneously. Status information makes it easier to handover projects between different employees and to monitor a project’s progress.

Production managers can now gain comprehensive insights into all production orders and performance indicators at a glance: The monitoring dashboards provide detailed analytics, allowing you to track the progress of your orders, identify bottlenecks, and make data-driven decisions to optimise processes effectively. The central overview sums up important information about all of your orders and comments. Furthermore, a detailed view provides you with data e.g. about processing times and material consumption. In addition, you can export a production report for each order.

EPLAN Software for Planning and Assembling Control Cabinets

With EPLAN you always have the appropriate software to hand in order to efficiently master current challenges, from manufacturing to operations.

EPLAN Smart Mounting supports the manual assembly of control cabinets

EPLAN also provides step-by-step support for assembling control cabinets and equipping them with electrotechnical components using EPLAN Smart Mounting. Combined with EPLAN Smart Wiring, control cabinet assembly is made quicker and easier, ensuring consistent high quality, even with a shortage of skilled workers.

EPLAN Pro Panel for planning control cabinets and switchgear systems in 3D

The digital twin from EPLAN Pro Panel is available as a solid foundation of data for production and thus also makes it ready for using EPLAN Smart Wiring. This means that cabling technicians don’t have to invest any additional effort in compiling documentation and can fully focus on their work assembling the control cabinet.

EPLAN Smart Wiring in Practice

Find out how companies use our solutions to address current technical and business developments and improve their productivity.

EPLAN Tutorials

Moving images explain things better! That’s why we’re providing free of charge tutorials that support you in the daily use of our solutions.

System Requirements

What hardware and software requirements should your system meet for the use of the EPLAN Platform?

Highlights around the current release

Get an overview of innovative functionalities that make your project planning more efficient.

We’re Here for You!

EPLAN offers you comprehensive services and support beyond our software. We’re looking forward to supporting you!

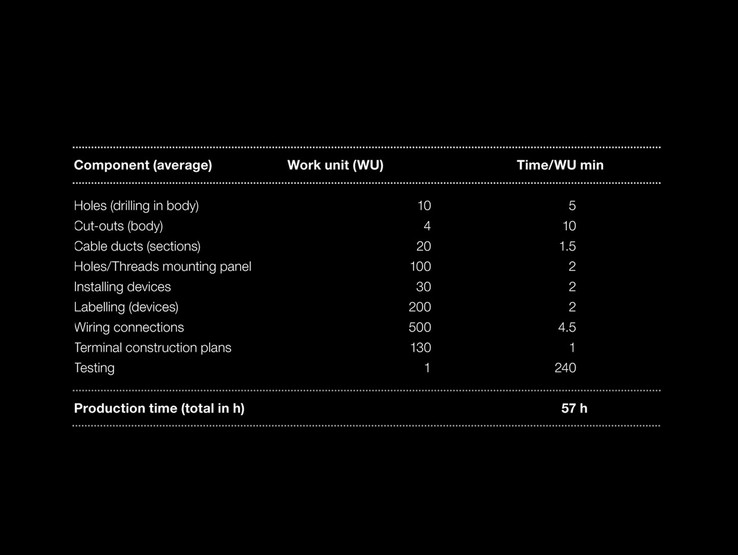

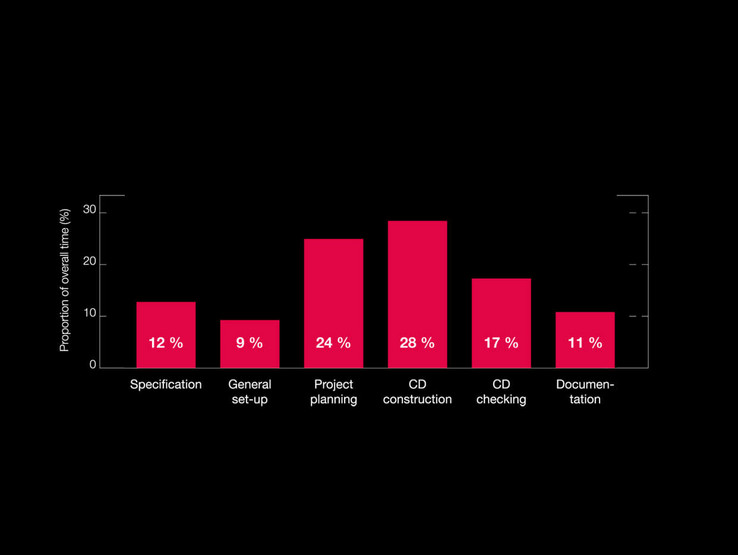

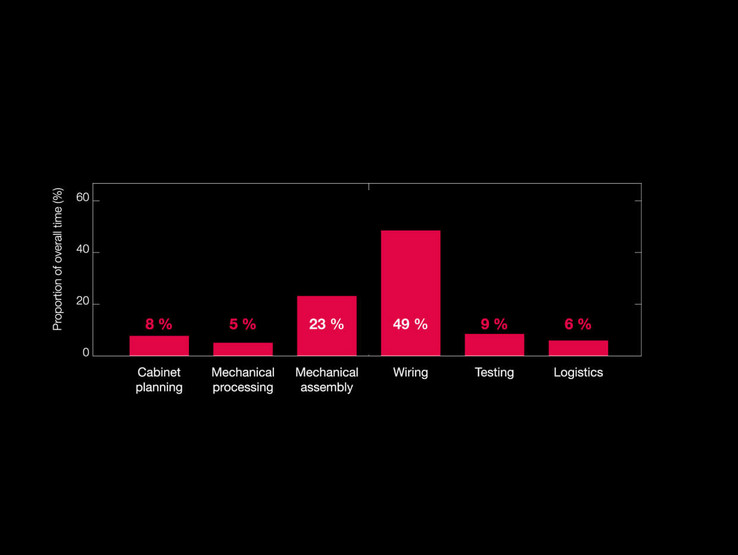

Control Cabinet Engineering 4.0 Study

Is it worth introducing automation for manufacturing and engineering processes in panel building? You’d better believe it – and for both large corporations and smaller companies. The “Control Cabinet Manufacturing 4.0” study by the Institute for Control Engineering of Machine Tools and Manufacturing Units (ISW) of the University of Stuttgart delivers the figures, data and facts about it. Is your curiosity piqued? Then download the study, which is free of charge and available exclusively from EPLAN.

We’re Happy to Help!

Please contact us if you’d like to learn more about EPLAN Smart Wiring. We’re looking forward to helping you.