Support for your suppliers:

Electrical schematic documentation made simple and clear

As a plant operator, what are your expectations from your suppliers? EPLAN is happy to assist you in establishing precise specifications and standards for your supplier guidelines. This will ensure that your project documentation becomes a reliable source of data for the maintenance and servicing of your machinery and plant systems.

Are your plant operations heading in the right direction?

Let’s take this journey together!

Are you receiving confusing documentation from your suppliers? It doesn’t have to be this way!

Production lines rely on the expertise of multiple suppliers who handle the design, delivery, and commissioning of machines and systems. And, while we are generally satisfied with this set up, it would be better if design approvals weren’t so chaotic.

Each supplier provides their documentation in a unique data format, and some even rely solely on printed materials. With an overwhelming amount of schematics spanning thousands of pages, it becomes nearly impossible for us to keep track of whether the information is complete and free of errors. It’s only when something isn’t working properly that these shortcomings become apparent and at that point we cannot identify the cause.

Electrical documentation – Guidelines for suppliers

EPLAN helps you to create clear guidelines for suppliers to ensure that you have access to standardised plant system documentation at all times. Regardless of the number of service providers you collaborate with, rest assured that acceptance procedures will run smoothly and that crucial information will be accessible in standardised data formats.

Recommended specifications for project documentation

- Define the version of EPLAN

- Define the norms and standards

- Define the functional representation for the schematics

- Provide template projects as examples

- Define structuring systems and terminology

- Provide an approval lists for materials

Advantages of standardised supplier guidelines

- Standardised data for describing and documenting your automation systems

- Simple verification and quality assurance for the documentation

- Fast procurement of spare parts thanks to clear material guidelines

- Standardised working foundation for your service technicians

- Clear communication and optimal collaboration with suppliers

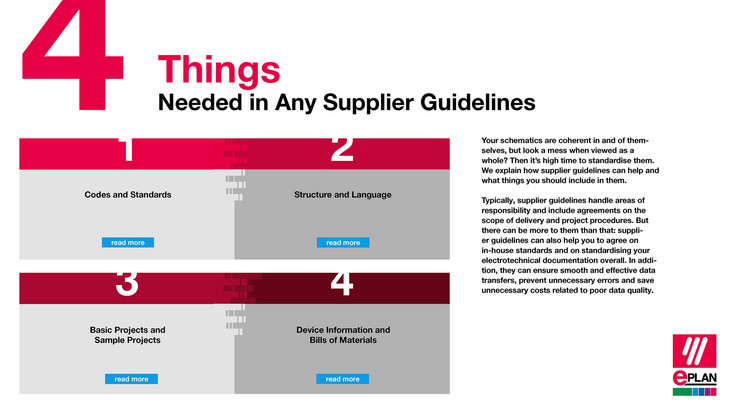

Your supplier guidelines for electrical design must include these four things!

Use our tips and tricks to create standardised specifications for your suppliers for the electrotechnical documentation of your machines and plant systems.

How EPLAN helps you define your supplier guidelines

With our services we help you in defining clear guidelines for your suppliers.

Use an EPLAN project template for the basis of your own guidelines

Did you know that EPLAN offers you a collection of standardisation templates and application examples for your projects? For example, template projects are available that you can use as the basis for your supplier guidelines. Simply register and use them at no additional cost!*

*Technical requirement is the creation of an EPLAN ID connected to a company organisation

Create approved lists for components and devices

Use the EPLAN Data Portal to create your own device database that you can forward to your suppliers and service providers. This allows you to quickly and easily define which components can be installed in your systems.

Personalised consulting for defining your supplier guidelines

Would you like to put together a comprehensive set of rules and guidelines for your suppliers and need support on the topic of electrical designs? Our experienced EPLAN consultants are happy to provide you with advice and support.

Training courses for suppliers of plant operators for the automotive industry

EPLAN offers suppliers of plant operators such as Volkswagen and Mercedes Benz their own bespoke training programme specifically dealing with the currently applicable guidelines. If you would also like support in the systematic training of your suppliers, we’re happy to help.