EPLAN: More than ECAD

Digital electrical engineering documentation for efficient plant operations

Is your documentation printed on paper? How difficult is it to find that documentation when operations come to a halt? And when you do find it, is it even up-to-date? Luckily, EPLAN can assist you and your suppliers quickly and easily in generating top-notch, constantly up-to-date documentation for your automation systems. This forms the foundation for uninterrupted operations as these have already been established during the electrical design phase.

Are your plant operations heading in the right direction?

Let’s take this journey together!

Be honest: Does inadequate documentation increase downtime in your plant?

Do you recognise this scenario? Production runs smoothly as long as the plant systems are functioning properly. However, when a malfunction arises, chaos ensues: What is the exact cause? How can our technician locate the specific components that need replacement among hundreds, or even thousands, of schematic pages – especially if the documentation is not up to date?

PDF documents can be just as confusing as folders filled with printed schematics covered in sticky notes. Consequently, production comes to a costly halt!

Why choose EPLAN? It’s a documentation tool for plant operators and their suppliers!

High-quality documentation of automation systems is crucial for seamless operations in industrial plants. However, relying solely on PDFs for technical documentation often lacks detailed information behind the schematic graphics. To address this, ECAD software proves to be a more suitable option, especially for electrotechnical documentation.

However, EPLAN takes it a step further by enabling machine suppliers to store comprehensive digital data within their schematics, including associated documentation. This creates a complete digital description of the automation systems, making it easier to commission new equipment and accept new plant systems. Furthermore, it simplifies troubleshooting during operations and facilitates future expansions.

Benefits for plant operators: electrical documentation with EPLAN

- At any moment, users have the ability to access all electrical information related to their project.

- The integrated device includes data from hundreds of manufacturers, providing users with a comprehensive and diverse range of information.

- Documentation such as bills of materials, terminal diagrams, etc. can be easily generated from the schematics.

- Changes need to be made only once and will be automatically applied to the entire project.

⇒ Smooth commissioning and expansion of plant systems

⇒ Fast response times in event of malfunctions

Different schematic views based on your documentation

- Central ‘navigator view' provides a comprehensive overview of your schematics and components

- Terminal assignment diagrams and component overviews

- Complete automation system site plans

- Clear functional markings in accordance with IEC 81346

- Traceable change processes

⇒ A solid data foundation for clear documentation

⇒ Evaluations and test runs are possible with just a few clicks

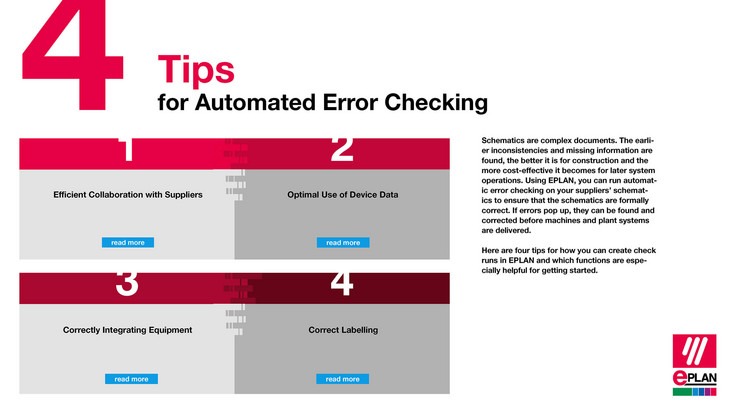

Boost the quality of your electrical documentation by using check runs: Four tips

EPLAN's automatic check runs provide a quick and efficient way to determine the quality and comprehensiveness of your documentation. In just a matter of minutes, you can effortlessly identify any errors like duplicate device tags, open connections, or components without assigned parts. Here are four tips about how to set up your error checking with EPLAN in the best way possible.

EPLAN's software and services for your uninterrupted plant operations

Discover our software and services for efficient and safe plant system operations. We’re happy to advise you on this!

High-quality software – now and in the future

EPLAN offers you the most powerful software for electrical engineering. Our software’s development is delivered to the needs of our users. We recommend that you always use the most current version of EPLAN so that you always benefit from the latest technology and seamless integration to our cloud collaboration and data solutions.

Easily exchange components based on device data

Use a huge selection of the latest device and component data from popular manufacturers to provide your suppliers with exact specifications for using components. Your service technicians will benefit from the comprehensive parts descriptions and device information.

View, document and share digital schematics anywhere

Make your schematics digitally available for service technicians anywhere, even without an EPLAN licence. Changes made can be digitally documented while still onsite via redlining on the schematics, electrical designers can then check the changes and update the documentation in no time at all.

Comprehensive services – from eLearning courses to individual consultation

EPLAN offers you a comprehensive range of support, training and consulting services. In just a few minutes of exploring our eLearning courses, you'll gain valuable insights, such as tips on designing terminals and cabling, not to mention guidance on the related documentation.